Technologies

The goal of the company is to develop applications of polymer composite materials in Russia on a base of existing European technologies as well as with using company’s own research.

Use innovative technologies for the production of composite products make it possible to create products that are characterized by high accuracy of parameters and quality. You have the opportunity to order parts in the required quantity, and the Sagrit Company will complete the work in a short time.

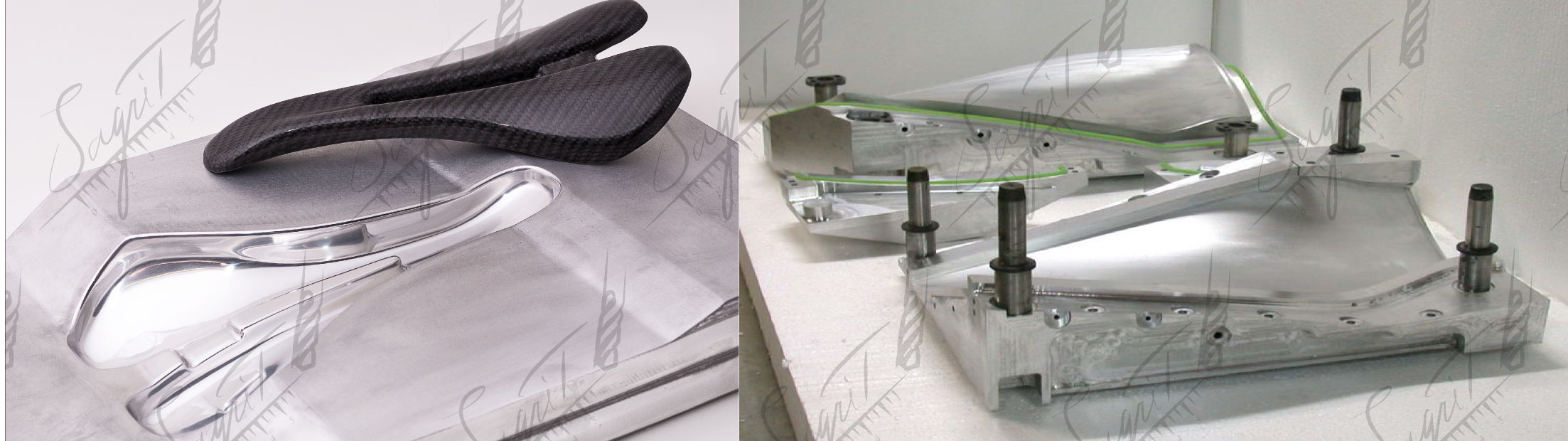

We use the method of impregnation under pressure, vacuum forming of plastic, vacuum infusion, manual laying and spraying, molding from prepregs, as well as the technology of pressing from sheet molding materials. The choice of a particular method should be carried out depending on the requirements for quality, characteristics, chemical, thermal resistance and other parameters. The size of the batch also plays a role.For production medium and large series, prepreg pressing technology is used. And for the production of small and medium series, taking into account the size of the parts, spraying or vacuum infusion is chosen. The production of highly loaded products, which are subject to certain quality requirements, is carried out using the RTM method.

We use a wide range of different technologies for production of reinforced plastics and vacuum-formed products: RTM, vacuum infusion, spraying, molding of SMC prepregs, as well as pressing prepregs and reinforced thermoplastics (GMT, LWRT, Loprefin).

In this section, you can find more detailed information on each technology used, including product quality, design possibilities and limitations.

To use technologies for the production of composite products, please contact us at +7 (495) 642-86-52 and take advantage of the advice from specialists who will tell you which technique is suitable for manufacturing, taking into account individual tasks.