Short description of the technology

During this process, resin-soaked fiber mats are inserted into an open one-shell mold. More resin is introduced and consolidated via hand rollers.

Advantages and restrictions of the technology

The main advantages of hand lay-up and spray-up:

• The cheapest method of production for prototypes and small series;

• The possibility to produce very large and complex-shaped parts;

• The possibility to adjust the part’s properties during the production process (by changing the thickness and type of reinforcement).

However, this process is very time-consuming, so it is ill-suited for series production. The quality of the rear of the part is also frequently poor (low thickness accuracy).

Part design

The manual application of the material allows some parameters, such as thickness and resin content, to be altered during the process. It is also possible to manually put some inserts or reinforcing elements into the part. However, as is usual with manual control, accuracy is not very high and small radii cannot be achieved.

The possibilities and restrictions of part design for hand lay-up and spray-up are described in detail in table below.

Table. Design of parts made by hand lay-up and spray-up

| Finished surfaces |  |

|

| Thickness accuracy, mm |  |

|

| Minimum inside radius, mm |  |

|

| Molded-in holes |  |

|

| Undercuts |  |

|

| Minimum thickness, mm |  |

|

| Maximum thickness, mm |  |

|

| Metal inserts |  |

|

| Ribs |  |

|

| Bosses |  |

|

| Molded-in labels |  |

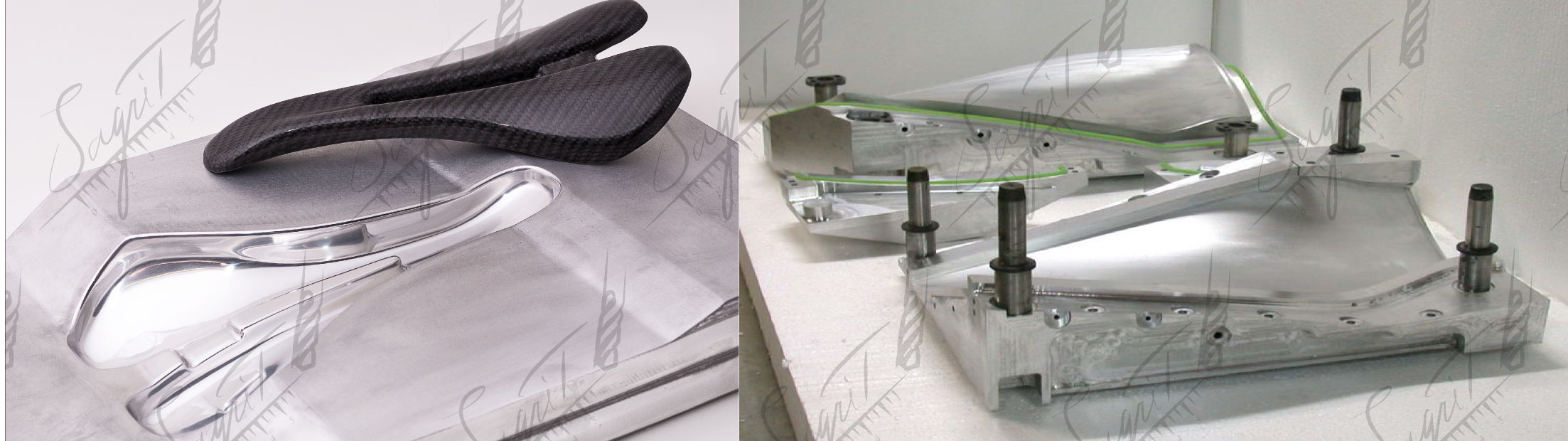

We use hald lamination for producing large parts, when the clients wants to minimize costs – for example for the production of prototypes.

Hand lamination process

We can produce complex parts with high-quality surface

Mask of the train head, made by hald lamination

Spray-up method is used for speed-up and for lowering costs. It is the most inexpensive method that we use for FRP parts production. Mixture is sprayed-up usually on the plastic base so that the high quality surface can be obtained.

Spray-up process