Short description of the technology

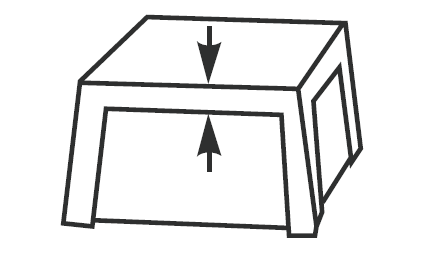

SMC (sheet molding compound) is a type of semi-finished product (resin mixed with fibers, fillers and additives) that is processed under high pressure in heated molds. In this process, SMC becomes fluid and fills the cavity of the mold.

Advantages and restrictions of the technology

The main advantages of SMC compression molding:

• Very high accuracy;

• Very short cycle time (suitable for mass production);

• Equal mechanical properties in all directions (quasi-isotropic);

• Low price of the materials.

Due to the short fiber length, parts made of SMC composite material have lower mechanical properties compared to composite material made of fabrics (prepreg molding, RTM and vacuum infusion).

Another disadvantage of this method is the huge investment required for tools – these are usually made of high-quality steel that can withstand the scraping force of fibers.

Part design

The fluid state of SMC composite during the molding process allows complicated parts to be made with variable thickness, and with ribs, bosses and inserts. This technology is widely used in the automotive industry because it can produce a large quantity of parts at a low cost. Such parts, if properly designed, can replace several metal components at once.

The possibilities and restrictions of part design for SMC compression molding are described in detail in the table below.

Table. Design of parts made by SMC compression molding

| Finished surface |  |

|

| Thickness accuracy, mm |  |

|

| Minimum inside radius, mm |  |

|

| Molded-in holes |  |

|

| Undercuts |  |

|

| Minimum thickness, mm |  |

|

| Maximum thickness, mm |  |

|

| Metal inserts |  |

|

| Ribs |  |

|

| Bosses |  |

|

| Molded-in labels |  |

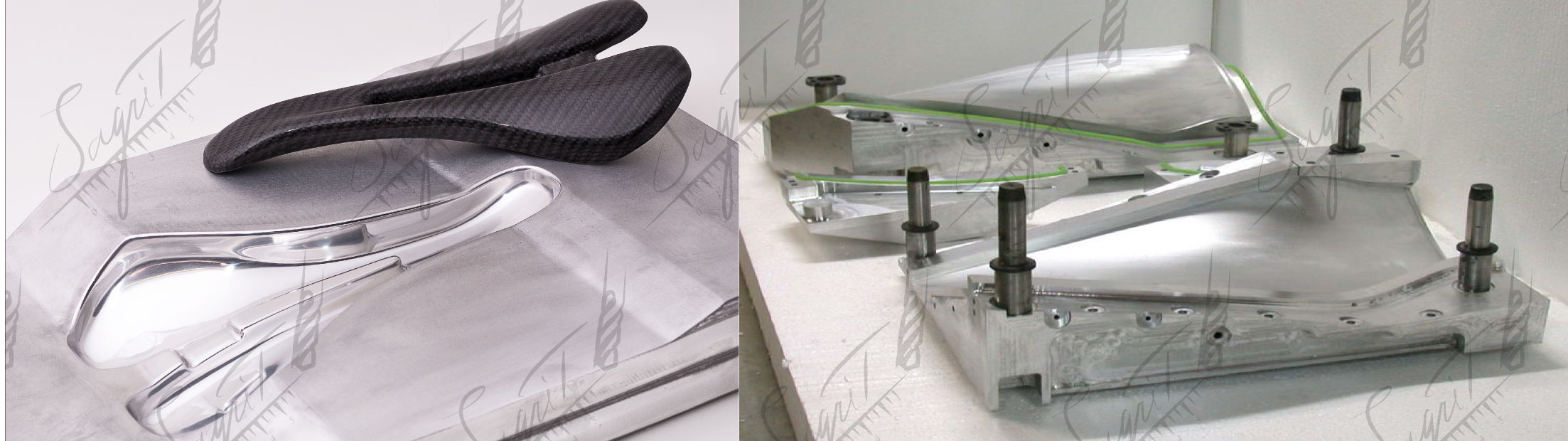

We have all the necessary equipment for SMC parts production. We can design and produce molds for SMC compression molding. Molds for SMC compression molding usually have installed heaters and the part extraction system.

Hydraulic press for SMC compression molding (plate size 1.5х1.3m, 350 tons)

Low costs of the material and high performance of the technology let us produce different parts, for example, sanitary tiles.

Сантехническая плитка из SMC-композита