In the realm of composite material production, innovation is the key to unlocking unparalleled quality and efficiency. One such groundbreaking innovation is vacuum infusion technology. With industry leaders like Sagrit championing its adoption, this technology is set to redefine the standards of composite production. Let’s delve deeper into the intricacies of vacuum infusion, its myriad benefits, and its transformative impact on the industry.

Understanding Vacuum Infusion

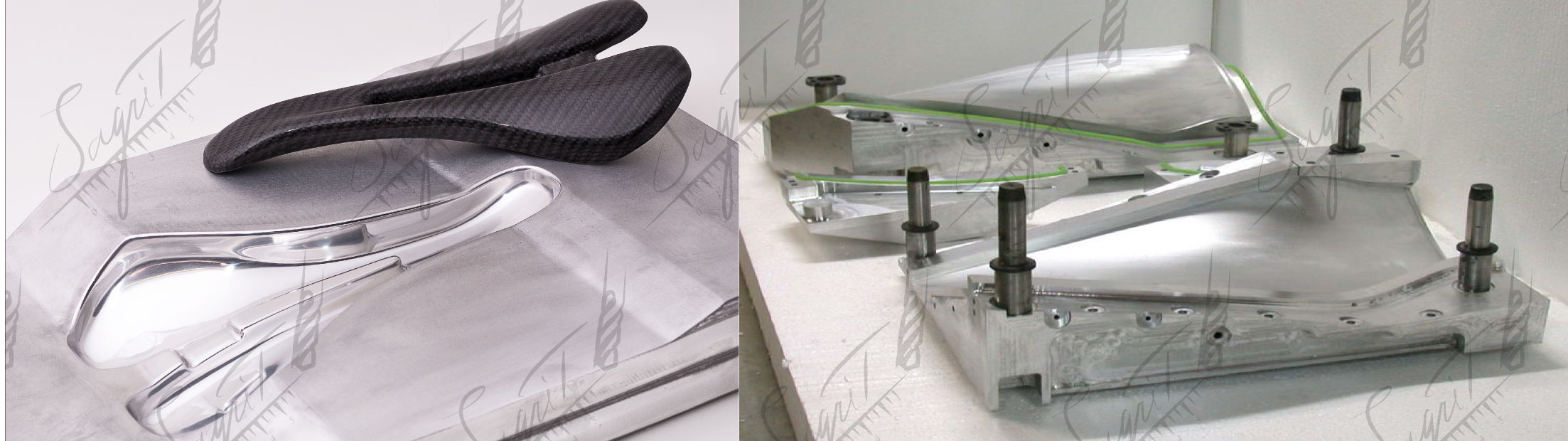

At its core, vacuum infusion is a process that involves the use of a vacuum to draw resin into a laminate. Materials are laid dry into the mold, and the vacuum is applied before the resin is introduced. Once the vacuum is established, resin is infused into the laminate, ensuring a consistent and high-quality composite part.

The Process: Precision and Perfection

The vacuum infusion process begins with the placement of a dry reinforcement in the mold. A vacuum bag is then placed over the mold, sealing it completely. When the vacuum is applied, it removes air and volatiles, creating a void-free environment. Resin is then introduced, filling the voids and saturating the reinforcement, resulting in a high-quality composite part with a consistent resin-to-fiber ratio.

Benefits: Why Vacuum Infusion Stands Out

- Superior Quality: The controlled environment ensures minimal air entrapment, leading to void-free laminates with superior mechanical properties.

- Efficient Resin Usage: The process ensures optimal resin-to-fiber ratios, minimizing waste and ensuring cost-effectiveness.

- Safety First: With minimal exposure to volatile organic compounds (VOCs), the process is safer for operators.

- Versatility: Suitable for a wide range of materials and mold sizes, offering flexibility in production.

Sagrit’s Role in Championing Vacuum Infusion

As pioneers in the composite material industry, Sagrit recognizes the potential of vacuum infusion technology. With a commitment to quality and innovation, Sagrit has integrated this technology into its production processes, ensuring products that are not only durable but also environmentally friendly. With a team of experts and state-of-the-art facilities, Sagrit is at the forefront of bringing the benefits of vacuum infusion to a global audience. For collaborations or insights, reach out to Sagrit at +7 (495) 642-86-52.

Conclusion: The Future of Composite Production

Vacuum infusion technology, with its myriad benefits, is set to become the gold standard in composite material production. As industries worldwide strive for efficiency, sustainability, and quality, this technology offers a solution that meets all these criteria. With leaders like Sagrit leading the charge, the future of composite production looks brighter, more innovative, and more efficient than ever before.