In the dynamic world of composite materials, the quest for perfection is ceaseless. Among the myriad of techniques employed, Resin Transfer Molding (RTM) stands out as a beacon of excellence. With Sagrit’s unwavering commitment to quality, RTM has become a cornerstone in producing composites that are not only high in quality but also durable. Let’s embark on an exploration of RTM, its profound significance, and its transformative impact on composite production.

Deciphering RTM: A Glimpse into the Process

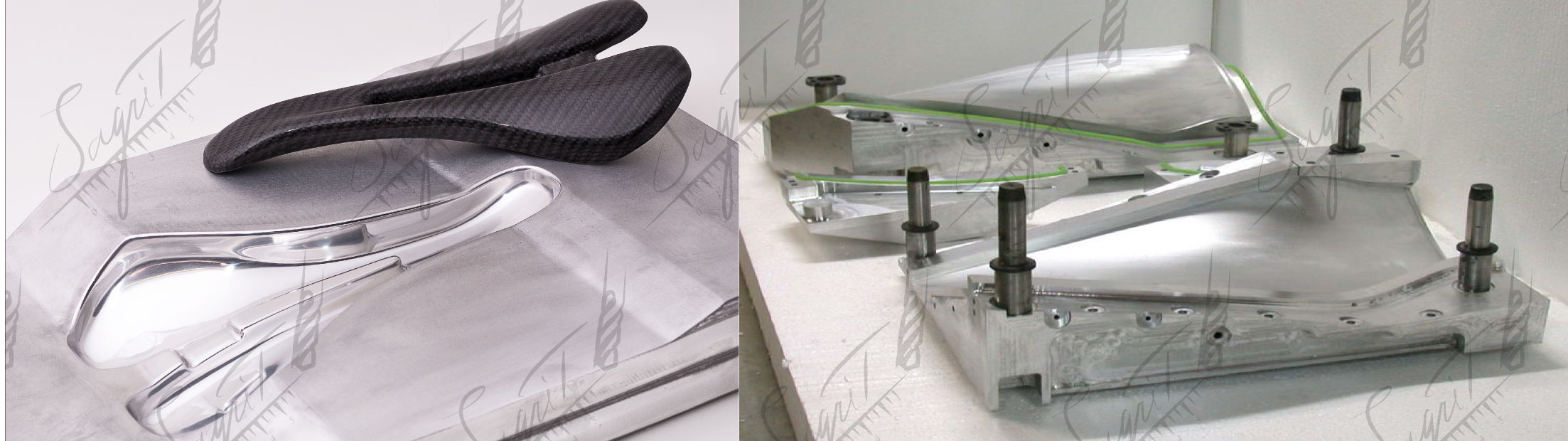

Resin Transfer Molding, commonly known as RTM, is a low-pressure closed molding process. It involves injecting liquid resin into a closed mold containing dry fiber reinforcements. The resin, once infused, cures and solidifies, resulting in a high-quality composite part. The process is meticulously controlled, ensuring precision and consistency in every product.

Why RTM? Unveiling the Benefits

- Precision Perfected: The closed mold system ensures a controlled and consistent resin flow, leading to uniform and void-free laminates.

- Optimal Fiber Volume: RTM allows for higher fiber volume fractions, translating to composites with superior mechanical properties.

- Versatility at its Best: The process is adaptable, catering to a wide range of reinforcement materials and resin systems.

- Eco-friendly Approach: With minimal emissions and waste, RTM is a step towards sustainable composite production.

Sagrit’s Endeavor with RTM

Sagrit, as a trailblazer in the composite industry, has embraced RTM technology wholeheartedly. Recognizing its potential in crafting premium products, Sagrit has integrated RTM into its core production processes. With a team of seasoned experts, state-of-the-art facilities, and a passion for innovation, Sagrit is redefining the standards of composite production. For deeper insights or potential collaborations, Sagrit welcomes you to connect at +7 (495) 642-86-52.

RTM: The Future of Composite Production?

The composite industry is ever-evolving, with technologies emerging and fading. However, RTM, with its myriad advantages, seems poised to remain a stalwart. As industries globally prioritize quality, durability, and sustainability, RTM offers a solution that aligns perfectly with these objectives. With industry leaders like Sagrit championing its cause, RTM’s role in producing high-quality composite materials is not just significant; it’s transformative.

In conclusion, Resin Transfer Molding is more than just a technology; it’s a testament to the industry’s commitment to excellence. As we look ahead, with companies like Sagrit leading the way, the future of composite materials shines bright, promising products that are not only of superior quality but also crafted with precision and care.